Interview partner: Hannes Ehrlich, former Product Manager DOCUFY Machine Safety

What is DOCUFY Machine Safety and what can it do?

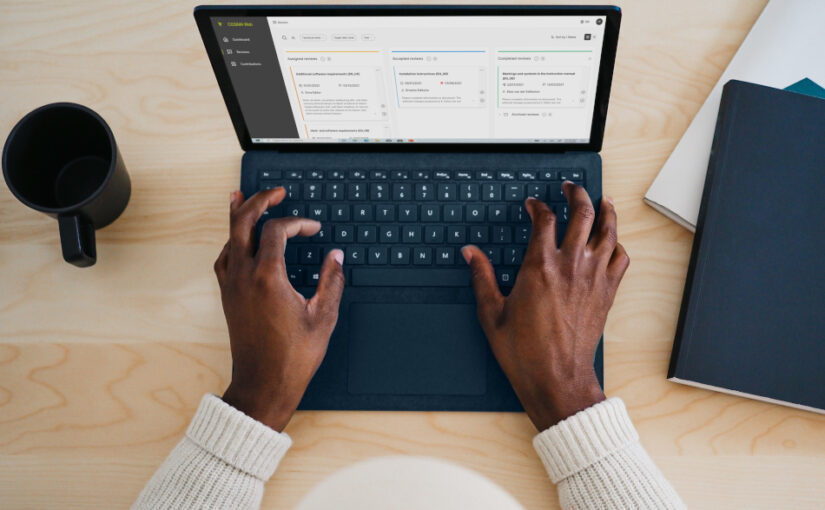

DOCUFY Machine Safety is our specialist software for the compliant generation of risk assessments. It enables users to utilize all documented content right away by means of a sophisticated modularization concept.

What are the advantages of DOCUFY Machine Safety for me and how does DOCUFY Machine Safety alter my everyday work?

Because all content only has to be generated one single time, the effort required to generate risk assessments decreases with every piece of content that is documented. In addition to this, its project management and progress monitoring functions enable convenient risk assessment during the construction process – and all of this in line with the requirements of the EC Machinery Directive.

On the basis of which evaluation criteria can I generate my risk assessment?

Both classic, iterative risk assessments in line with the EC Machinery Directive and risk assessments according to standard requirements as set out in article 7 of the EC Machinery Directive are possible. Explosion risk assessments in line with the ATEX Directive and risk assessment according to the Low Voltage Directive continue to be supported.

How does DOCUFY Machine Safety fit into the DOCUFY product portfolio?

We want to utilize and harness the potential of technical documentation information for all business units, which includes marketing, sales and so on. For this reason, our products perfectly interlock with one another. Our Component Content Management System COSIMA, for example, helps users to create technical documentation quickly and compliantly, whereas DOCUFY Machine Safety assists in the generation of legally compliant risk assessments. The key point here is that COSIMA and DOCUFY Machine Safety are connected with one another. Warnings and security notices, images and PDFs from risk assessments can be directly referenced in technical documentation or edited. And, at the end, TopicPilot enables all of this content to be published digitally and device-specifically, both on and offline. This means: If a service technician needs urgent information about a certain machine, it can be provided to him or her on the go – that is: while he or she is standing in front of the machine – via a tablet or smartphone. This is a huge development and helps to move the process away from outdated documentation on paper to a mobile platform – and the keyword here is #eDok.

What was your funniest/loveliest/most interesting moment with DOCUFY Machine Safety?

The most interesting moment was probably my very first project. We had gathered together the data of a large Scandinavian mechanical engineering company and that was a real eye-opener for me. The software really proved itself: The process was seamless and went off completely without a hitch. It was really a great project – for us and for the mechanical engineering company.